A

belt drive is a type of power

transmission system that uses belts to transfer power between two rotating

shafts. The belts used in a belt drive system are typically made of rubber or

other flexible materials, and they wrap around the pulleys or sheaves on the

shafts. When one shaft rotates, the belt transfers the rotational energy to the

other shaft, causing it to rotate as well.

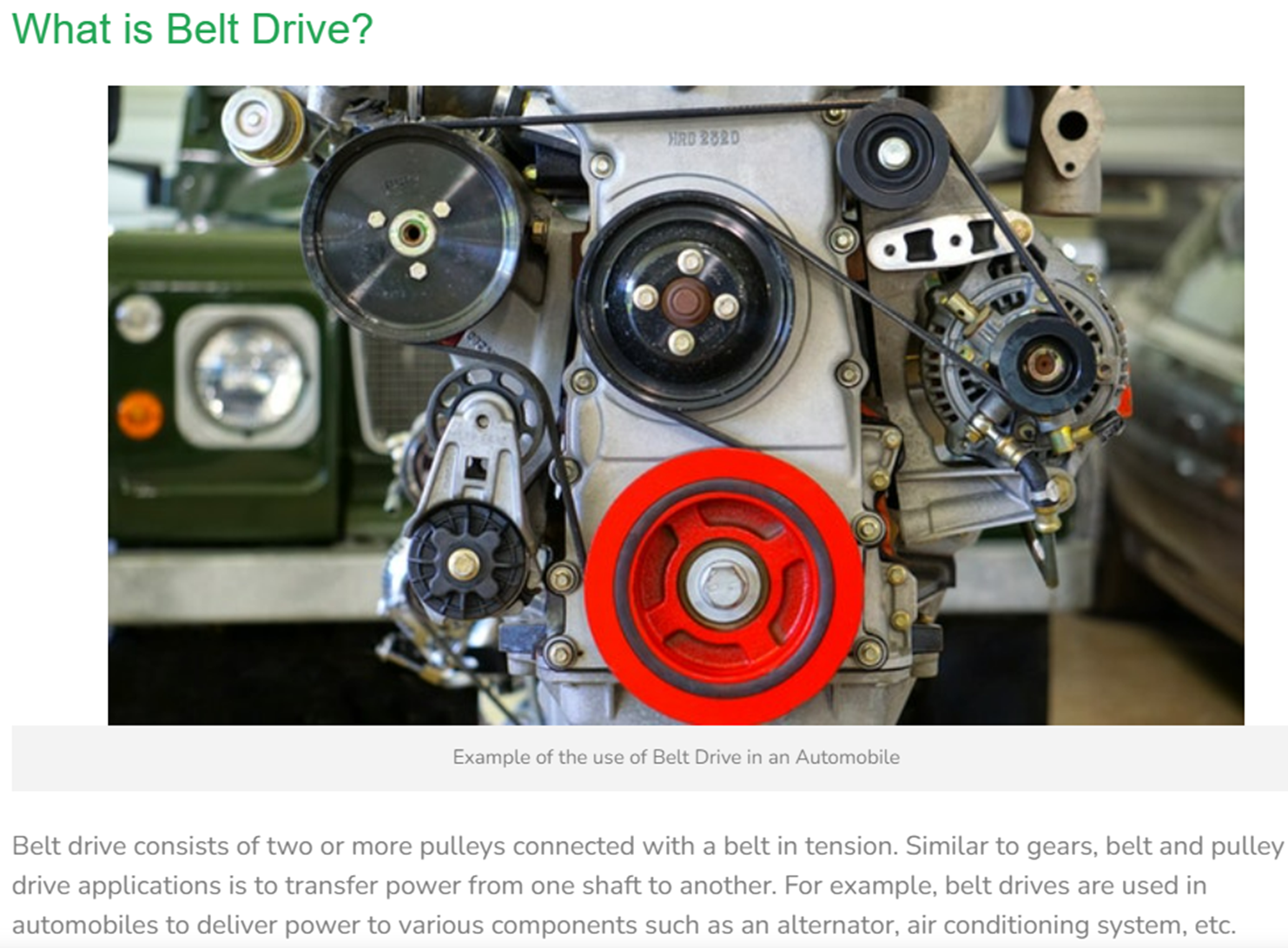

Belt

drives are commonly used in a wide range of applications, from simple machinery

to complex systems. They offer several advantages over other types of power

transmission systems, including their ability to handle shock loads, their

relative ease of maintenance and installation, and their ability to operate

smoothly and quietly.

There

are several types of belt drives available, each with its own unique

characteristics and advantages. Some of the most common types of belt drives

include flat belt drives, V-belt drives, timing belt drives, ribbed belt

drives, and chain drives.

Flat

belt drives are the simplest type of belt drives, and they are typically used

in low-power applications. V-belt drives are the most common type of belt

drives and are suitable for high-power transmission applications, while timing

belt drives are used in applications that require precise synchronization

between the driving and driven shafts. Ribbed belt drives, also known as

serpentine belt drives, are used for multiple accessory drives, while chain

drives are used in heavy-duty applications where high power transmission is

required.

When

selecting a belt drive system, several factors should be considered, including

the power requirements of the system, the distance between the shafts, and the

speed of operation. By choosing the appropriate type of belt drive for a given

application, users can ensure reliable and efficient power transmission for

their machinery and equipment.

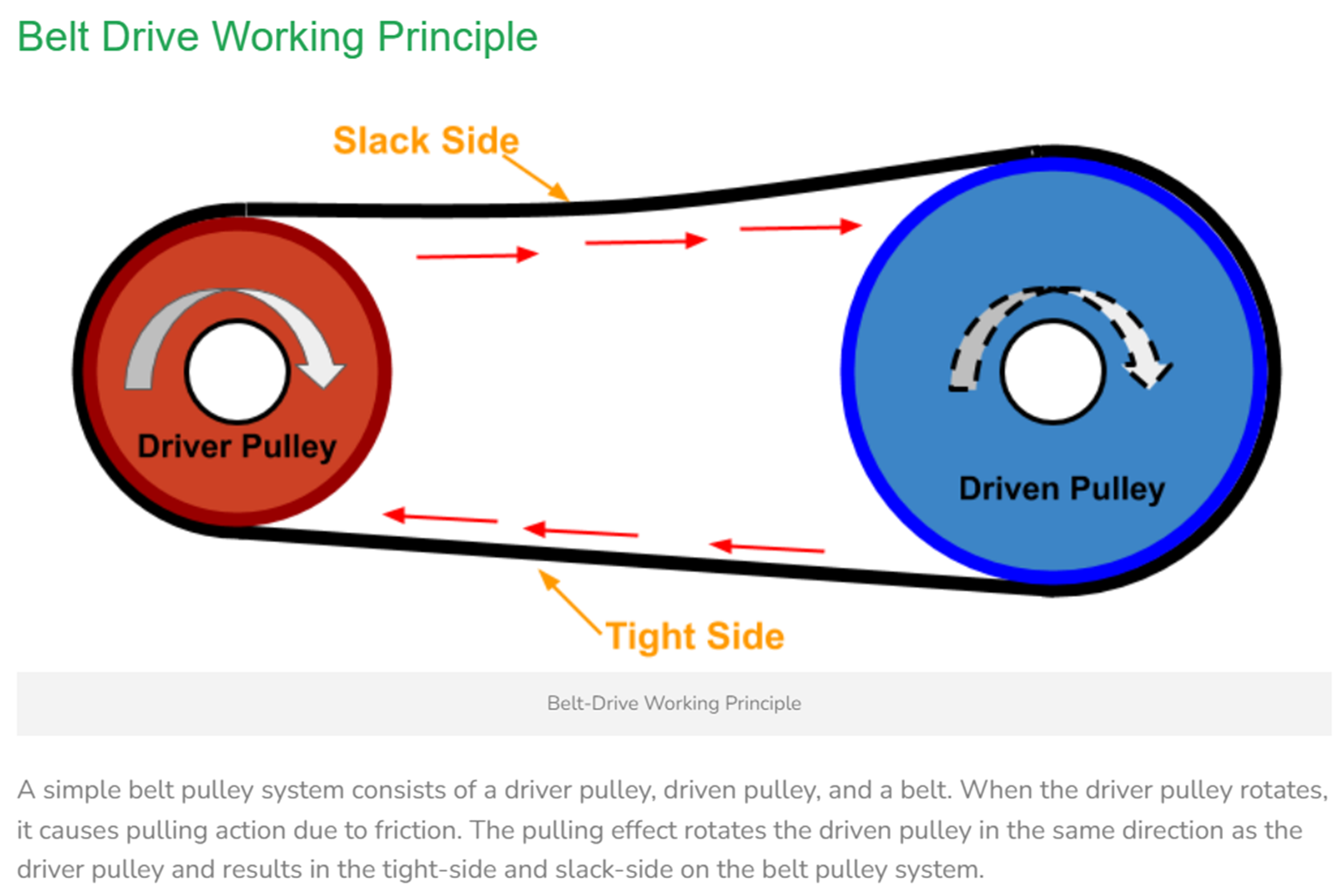

The

working principle of a belt drive is based on the transfer of power between two

rotating shafts using a flexible belt. The belt is wrapped around a set of

pulleys or sheaves on the two shafts, and as one shaft rotates, the belt

transfers the rotational energy to the other shaft, causing it to rotate as

well.

When

power is applied to the driving shaft, the belt begins to move around the

pulley or sheave. The movement of the belt creates a frictional force that

causes the driven pulley to rotate, thereby transferring power to the driven

shaft. The belt drive system operates smoothly and quietly due to the

flexibility of the belt, which helps to absorb any shocks or vibrations that

may occur during operation.

The

power transmission capacity of a belt drive is determined by the tension

applied to the belt and the coefficient of friction between the belt and the

pulley. Tension is applied to the belt through the use of an idler pulley or

tensioning device that maintains the proper tension on the belt during

operation. Proper tension is important for optimal power transfer, as too

little tension can result in slipping and reduced power transfer, while too

much tension can result in excessive wear and tear on the belt and pulleys.

Belt

drives are commonly used in a variety of applications due to their ease of

installation, low maintenance requirements, and ability to operate smoothly and

quietly. They are also capable of handling shock loads and high-speed

operations, making them a popular choice for many industrial applications. By

selecting the appropriate type of belt and pulley system for a given

application, users can ensure reliable and efficient power transmission for

their machinery and equipment.

There

are several types of belts used in belt drive systems, each with their own

unique characteristics and advantages. Some of the most common types of belts

include:

- Flat belts:

These are the simplest type of belts and are commonly made of rubber or

leather. They are typically used in low-power applications and are

suitable for short distances between shafts. Flat belts have the advantage

of being easy to install and maintain, but they are not suitable for

high-power transmission applications.

- V-belts:

These belts have a trapezoidal cross-section and are commonly used in

industrial applications. They are made of rubber and have high tensile

strength and excellent power transmission capacity. V-belts are suitable

for high-power transmission applications and can operate at high speeds,

making them a popular choice for many industries.

- Timing belts:

These belts have teeth on the inner surface that engage with corresponding

teeth on the pulley, providing precise timing and synchronization between

the driving and driven shafts. Timing belts are commonly used in

automotive engines and other machinery that requires precise timing.

- Ribbed belts:

Also known as serpentine belts, ribbed belts have multiple ribs on the

inner surface that fit into matching grooves on the pulleys. They are used

for multiple accessory drives and can transmit power to several components

simultaneously.

- Round belts:

These belts are made of rubber and have a round cross-section. They are

commonly used in applications that require high-speed operation and low

power transmission.

The advantages of using belts in power transmission systems include:

- Easy

installation and maintenance

- Smooth and

quiet operation

- Ability to

handle shock loads

- High power

transmission capacity

- Efficient

energy transfer

- Low cost

compared to other power transmission systems

- Flexibility

to work with different types of machinery and equipment.

By

selecting the appropriate type of belt for a given application, users can

ensure reliable and efficient power transmission for their machinery and

equipment.

12 Comments

BAK/21/CH/004